45 Degree Chamfer CNC Bit: A Comprehensive Guide

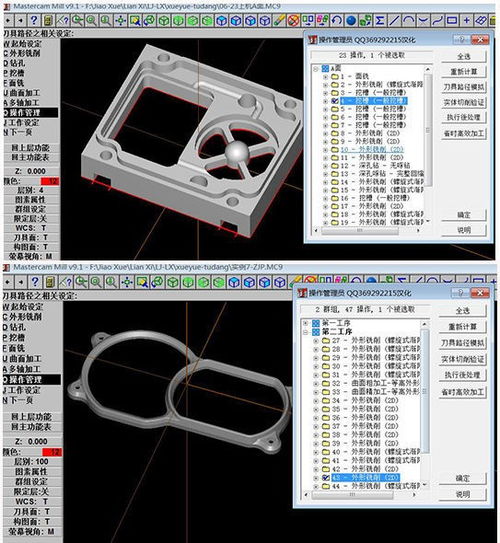

When it comes to CNC machining, the choice of cutting tools can significantly impact the quality and efficiency of the finished product. One such tool that has gained popularity in recent years is the 45 degree chamfer CNC bit. This versatile tool offers numerous advantages and is widely used in various industries. In this article, we will delve into the details of the 45 degree chamfer CNC bit, exploring its features, benefits, and applications.

Understanding the 45 Degree Chamfer CNC Bit

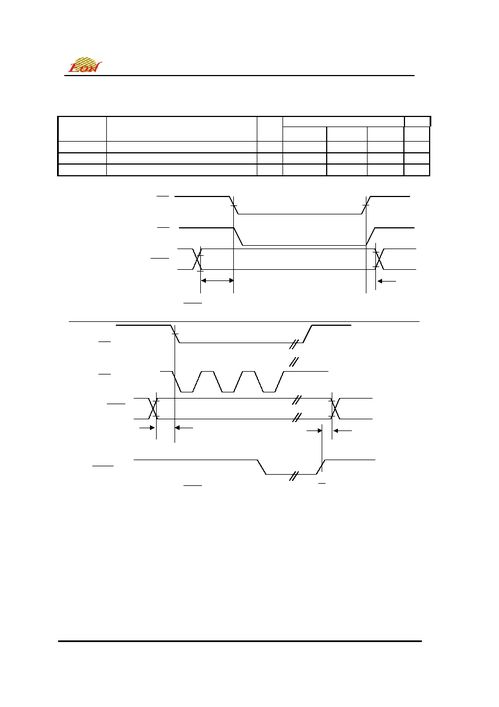

The 45 degree chamfer CNC bit, as the name suggests, features a 45-degree chamfer angle on its cutting edge. This unique design allows for the creation of chamfered edges, which are often used to improve the appearance and functionality of machined parts. The chamfer angle can be adjusted according to the specific requirements of the project, making this tool highly adaptable.

Features of the 45 Degree Chamfer CNC Bit

Here are some key features of the 45 degree chamfer CNC bit:

-

45-degree chamfer angle

-

High-quality materials, such as high-speed steel (HSS) or carbide

-

Various diameters and lengths available

-

Excellent cutting performance

-

Longer tool life

Benefits of Using the 45 Degree Chamfer CNC Bit

Using a 45 degree chamfer CNC bit offers several benefits:

-

Improved appearance: Chamfered edges provide a more refined and professional look to the machined parts.

-

Reduced stress: Chamfered edges help to reduce stress concentrations, which can lead to improved part durability.

-

Enhanced functionality: Chamfered edges can improve the fit and function of assembled parts.

-

Increased efficiency: The 45 degree chamfer CNC bit can be used to create chamfered edges in a single operation, saving time and reducing the need for additional finishing processes.

Applications of the 45 Degree Chamfer CNC Bit

The 45 degree chamfer CNC bit is widely used in various industries, including:

-

Automotive

-

Aerospace

-

Medical

-

Electronics

-

General engineering

Here are some specific applications:

-

Creating chamfered edges on automotive components, such as engine blocks and cylinder heads.

-

Producing chamfered edges on aerospace parts, such as turbine blades and engine casings.

-

Creating chamfered edges on medical devices, such as surgical instruments and implants.

-

Producing chamfered edges on electronic components, such as circuit boards and connectors.

-

Creating chamfered edges on general engineering parts, such as gears, shafts, and brackets.

Choosing the Right 45 Degree Chamfer CNC Bit

When selecting a 45 degree chamfer CNC bit, it is essential to consider the following factors:

-

Material: Choose a bit made from high-quality materials, such as HSS or carbide, to ensure durability and long tool life.

-

Diameter: Select a bit with the appropriate diameter for your project, ensuring that it fits the tool holder and the workpiece.

-

Length: Choose a bit with the appropriate length to reach the desired depth of cut.

-

Chamfer angle: Select a bit with the desired chamfer angle to achieve the desired edge finish.

Conclusion

The 45 degree chamfer CNC bit is a versatile and efficient tool that offers numerous benefits for CNC machining. By understanding its features, benefits, and applications, you can