Understanding Rotary Motion with Multiple Bits for Cutting Shapes

Rotary motion, a fundamental concept in mechanical engineering, plays a crucial role in various industrial applications. One such application is the use of multiple bits for cutting shapes. This article delves into the intricacies of this process, exploring the benefits, types of bits, and the technology behind it.

Benefits of Rotary Motion with Multiple Bits

Rotary motion with multiple bits offers several advantages over traditional cutting methods. Firstly, it allows for more complex shapes to be cut with precision and efficiency. This is particularly beneficial in industries such as aerospace, automotive, and妯″叿鍒堕€? where intricate designs are common.

Secondly, the use of multiple bits reduces the number of operations required to produce a part. This not only saves time but also reduces the risk of errors and increases productivity. Additionally, it minimizes the need for additional equipment, further reducing costs.

Lastly, rotary motion with multiple bits provides better control over the cutting process. This ensures that the final product meets the required specifications and quality standards.

Types of Bits Used in Rotary Motion

There are various types of bits used in rotary motion for cutting shapes. Some of the most common ones include:

| Bit Type | Description |

|---|---|

| End Mill | Used for cutting slots, pockets, and contours. Available in various shapes and sizes. |

| Ball End Mill | Similar to end mills but with a rounded tip, allowing for smooth cuts in corners. |

| Flute Mill | Used for cutting deep holes and slots. The flute design helps in chip evacuation. |

| Reamer | Used for finishing holes to a specific size and shape. Available in various sizes and materials. |

Each type of bit has its unique characteristics and is suitable for specific applications. The choice of bit depends on the material being cut, the desired shape, and the required precision.

Technology Behind Rotary Motion with Multiple Bits

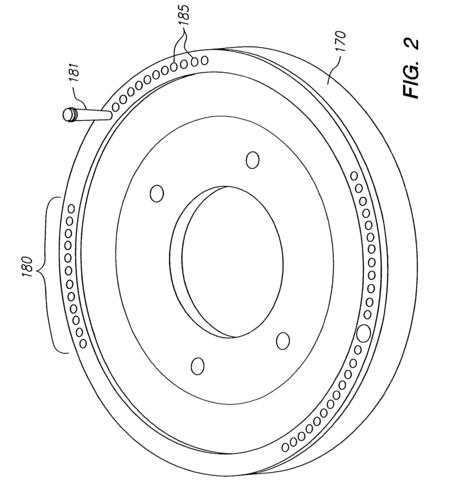

The technology behind rotary motion with multiple bits involves several key components:

- Spindle: The spindle is the rotating part that holds the bits. It is designed to provide high torque and precision, ensuring smooth and accurate cutting.

- Collet: The collet is a chuck that holds the bits securely in place. It is available in various sizes and types, allowing for the use of different bits.

- Control System: The control system is responsible for managing the cutting process. It includes software that allows for the programming of the desired shape and speed.

- Tool Holder: The tool holder is a component that connects the collet to the spindle. It ensures that the bits are aligned correctly and securely.

These components work together to provide a seamless and efficient cutting process. The control system allows for real-time adjustments, ensuring that the final product meets the required specifications.

Applications of Rotary Motion with Multiple Bits

Rotary motion with multiple bits finds applications in various industries, including:

- Aerospace: Used for cutting complex shapes in aircraft components, such as wings, fuselages, and landing gears.

- Automotive: Used for cutting engine parts, exhaust systems, and other components.

- Mold Making: Used for creating molds for plastic and metal parts.

- Medical Devices: Used for manufacturing precision parts for medical devices.

The versatility of this technology allows for the production of a wide range of products, from small components to large structures.

Conclusion

Rotary motion with multiple bits is a powerful and versatile technology that has revolutionized the way shapes are cut. Its benefits, including increased precision, efficiency, and productivity, make it an essential tool in various industries. As technology continues