Spot Weld Bit: A Comprehensive Guide

Are you looking to enhance your welding skills or simply curious about the tools used in the industry? The spot weld bit is a crucial component in the world of welding, especially in the automotive and metalworking sectors. In this detailed guide, we will delve into the various aspects of the spot weld bit, including its design, usage, and benefits. So, let’s get started!

Understanding the Spot Weld Bit

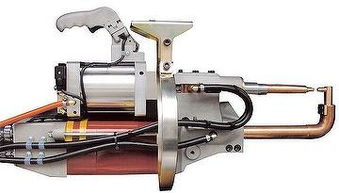

The spot weld bit is a specialized tool designed for creating spot welds, which are temporary connections between two metal surfaces. These welds are commonly used in the automotive industry to join car bodies and other metal components. The spot weld bit consists of a handle, a collet, and a bit, which is the part that makes contact with the metal surfaces.

Design and Construction

The design of a spot weld bit is crucial for its performance and durability. Here are some key aspects of its construction:

-

Handle: The handle provides a secure grip and is typically made of materials like plastic or metal. It is designed to be comfortable to hold and easy to maneuver.

-

Collet: The collet is a sleeve that holds the bit in place. It is usually made of metal and features a ratchet mechanism that allows for easy bit replacement.

-

Bit: The bit is the part that makes contact with the metal surfaces. It is typically made of high-quality steel and features a pointed tip to ensure a clean and precise weld.

Usage and Techniques

Using a spot weld bit requires proper technique and attention to detail. Here are some essential tips for achieving successful spot welds:

-

Positioning: Ensure that the metal surfaces are properly aligned before making contact with the spot weld bit. This will help create a clean and precise weld.

-

Pressure: Apply consistent pressure to the spot weld bit while making contact with the metal surfaces. Too much pressure can damage the bit, while too little pressure can result in an incomplete weld.

-

Speed: Welding speed is crucial for achieving the desired results. Too slow of a speed can cause overheating and damage to the bit, while too fast of a speed can result in an incomplete weld.

Benefits of Using a Spot Weld Bit

Using a spot weld bit offers several benefits, including:

-

Efficiency: Spot welding is a quick and efficient method for joining metal surfaces, making it ideal for high-volume production environments.

-

Strength: Spot welds are strong and durable, providing a reliable connection between metal components.

-

Cost-effectiveness: Spot welding is a cost-effective method for joining metal surfaces, as it requires minimal equipment and training.

Types of Spot Weld Bits

There are various types of spot weld bits available, each designed for specific applications. Here are some common types:

-

Standard Spot Weld Bit: This is the most common type of spot weld bit and is suitable for general-purpose welding tasks.

-

High-Force Spot Weld Bit: This type of bit is designed for applications that require a higher amount of force, such as welding thicker metal surfaces.

-

Specialty Spot Weld Bit: These bits are designed for specific applications, such as welding aluminum or other non-ferrous metals.

Maintenance and Care

Proper maintenance and care are essential for extending the life of your spot weld bit. Here are some tips:

-

Regular Cleaning: After each use, clean the bit to remove any debris or metal shavings. This will help prevent damage and ensure optimal performance.

-

Inspection: Regularly inspect the bit for signs of wear and tear. If you notice any damage, replace the bit immediately to avoid compromising the quality of your welds.

-

Storage: Store the spot weld bit in a dry, cool place to prevent rust and corrosion.

Conclusion

The spot weld bit is a versatile and essential tool for anyone involved in welding. By understanding its design, usage, and maintenance, you can ensure that you achieve high-quality spot weld