Understanding the Clutch Bit Screw: A Comprehensive Guide

The clutch bit screw, often overlooked yet crucial in various mechanical applications, is a small yet powerful component. Whether you are a DIY enthusiast or a professional mechanic, understanding the clutch bit screw can greatly enhance your work efficiency and safety. In this article, we delve into the intricacies of the clutch bit screw, exploring its design, applications, and maintenance.

Design and Composition

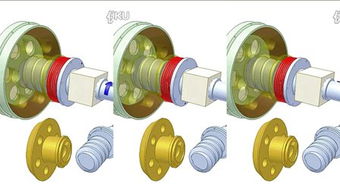

The clutch bit screw is typically made of high-quality steel, which ensures its durability and strength. Its design features a hexagonal head, which allows it to be easily tightened and loosened using a hex wrench. The screw’s shank is threaded, which enables it to engage with the clutch bit, creating a secure connection.

One of the key features of the clutch bit screw is its clutch mechanism. This mechanism allows the screw to engage with the clutch bit only when the bit is in the correct position, preventing damage to the bit or the workpiece. The clutch mechanism is usually a ratchet design, which ensures smooth and consistent engagement.

Applications

The clutch bit screw finds its way into various applications, from woodworking to metalworking. Here are some common uses:

| Application | Description |

|---|---|

| Woodworking | Used in drills and screwdrivers to secure bits and drill bits, ensuring precise and controlled drilling. |

| Metalworking | Used in drills and screwdrivers to secure cutting tools, allowing for smooth and accurate metal cutting. |

| Automotive | Used in automotive applications to secure various components, such as sensors and connectors. |

| Electronics | Used in electronics to secure components and connectors, ensuring a stable and reliable connection. |

Maintenance and Care

Proper maintenance and care of the clutch bit screw are essential to ensure its longevity and performance. Here are some tips:

-

Regularly inspect the screw for signs of wear or damage. If any issues are found, replace the screw immediately.

-

When not in use, store the clutch bit screw in a dry and clean environment to prevent rust and corrosion.

-

Use the correct size and type of clutch bit screw for the specific application to avoid damage to the tool or workpiece.

-

When tightening the screw, apply even pressure to prevent stripping the threads.

Choosing the Right Clutch Bit Screw

Selecting the right clutch bit screw for your application is crucial for optimal performance. Here are some factors to consider:

-

Material: Ensure the screw is made of high-quality steel to withstand the demands of your application.

-

Size: Choose the correct size of the clutch bit screw to fit your tool and workpiece.

-

Thread Type: Select the appropriate thread type for your application to ensure a secure and stable connection.

-

Clutch Mechanism: Consider the clutch mechanism to ensure smooth and consistent engagement with the clutch bit.

Conclusion

The clutch bit screw, a small yet powerful component, plays a vital role in various mechanical applications. By understanding its design, applications, and maintenance, you can ensure optimal performance and longevity. Whether you are a DIY enthusiast or a professional mechanic, investing in the right clutch bit screw can greatly enhance your work efficiency and safety.