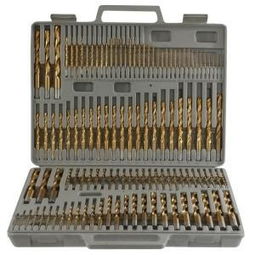

Titanium Drill Bits: A Comprehensive Guide

When it comes to drilling, the choice of drill bits can significantly impact the quality and efficiency of your work. Among the various types of drill bits available, titanium drill bits have gained popularity due to their exceptional performance and durability. In this article, we will delve into the details of titanium drill bits, exploring their features, benefits, and applications.

What are Titanium Drill Bits?

Titanium drill bits are designed with a core made of high-quality titanium alloy. The outer layer is typically coated with a durable material such as titanium nitride or titanium carbide, which enhances the bit’s lifespan and performance. These bits are commonly used in various industries, including construction, manufacturing, and metalworking.

Features of Titanium Drill Bits

Here are some key features that make titanium drill bits stand out:

- High Strength and Durability: Titanium is known for its exceptional strength and durability, making these drill bits highly resistant to wear and tear.

- Heat Resistance: Titanium drill bits can withstand high temperatures, which is crucial when drilling through materials that generate heat, such as metals.

- Corrosion Resistance: The titanium alloy used in these bits is highly resistant to corrosion, ensuring a longer lifespan and reduced maintenance.

- Reduced Friction: The coated surface of titanium drill bits reduces friction, resulting in smoother drilling and less wear on the bit.

- Improved Hole Quality: These bits produce cleaner, more precise holes, which is essential for various applications.

Benefits of Using Titanium Drill Bits

Using titanium drill bits offers several advantages:

- Increased Productivity: The high durability and performance of these bits allow for faster drilling, resulting in increased productivity.

- Cost-Effective: Despite their higher initial cost, titanium drill bits can be more cost-effective in the long run due to their longer lifespan and reduced maintenance.

- Improved Safety: The reduced friction and heat generation of these bits make them safer to use, reducing the risk of accidents.

- Enhanced Precision: The cleaner, more precise holes produced by titanium drill bits are ideal for applications that require high accuracy.

Applications of Titanium Drill Bits

Titanium drill bits are suitable for a wide range of applications, including:

- Woodworking: These bits are ideal for drilling holes in wood, as they produce clean, precise holes without damaging the wood.

- Metals: Titanium drill bits are highly effective for drilling through metals, such as steel, aluminum, and titanium.

- Plastics: These bits can also be used for drilling through plastics, producing clean, precise holes without clogging.

- Concrete and Masonry: Titanium drill bits are suitable for drilling through concrete and masonry, making them ideal for construction projects.

Types of Titanium Drill Bits

There are several types of titanium drill bits available, each designed for specific applications:

- Twist Drill Bits: These bits are suitable for general-purpose drilling in wood, metal, and plastic.

- Countersink Bits: These bits are used to create countersunk holes, which are essential for screw heads and other fasteners.

- Spade Bits: These bits are designed for drilling large holes in wood and soft metals.

- Forstner Bits: These bits are used for creating flat-bottomed holes in wood, ideal for mounting plates and other applications.

Choosing the Right Titanium Drill Bit

When selecting a titanium drill bit, consider the following factors:

- Material: Choose a bit that is suitable for the material you are drilling.

- Size: Ensure that the bit size matches the hole size you need.

- Shank Type: Select a bit with a shank type that is compatible with your drill.

- Coating: Consider the coating material for enhanced performance and durability.

Related Posts

ladybug larvae bite,Ladybug Larvae Bite: A Detailed Look into the Life of These Tiny Insects

Ladybug Larvae Bite: A Detaile…