Forstner Bit: A Comprehensive Guide

When it comes to precision machining, the Forstner bit stands out as a versatile and efficient tool. Designed to create clean, round holes in wood, plastic, and other materials, this tool has become an essential part of many workshops. In this article, we will delve into the details of the Forstner bit, exploring its history, design, applications, and maintenance.

History of the Forstner Bit

The Forstner bit was invented by John Forstner, a German immigrant to the United States, in the early 19th century. Initially designed for use in woodworking, the bit quickly gained popularity due to its ability to create smooth, round holes with minimal splintering. Over the years, the design has evolved, but the basic principle remains the same.

Design and Construction

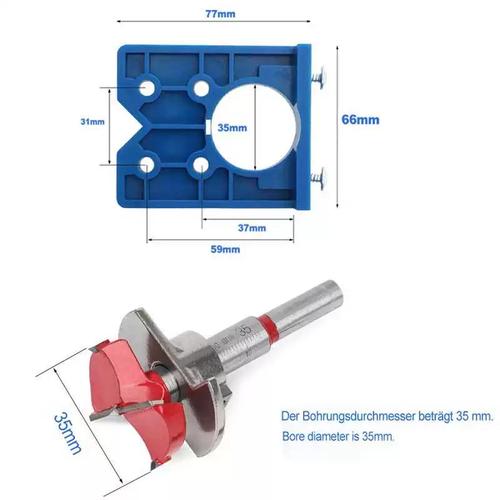

The Forstner bit is typically made of high-speed steel (HSS) or carbide, materials known for their durability and heat resistance. The bit features a central cutting edge, flanked by two or more flutes that remove chips from the hole. The design allows for a smooth, clean cut, making it ideal for intricate work.

Here’s a breakdown of the key components of a Forstner bit:

| Component | Description |

|---|---|

| Shank | The part of the bit that fits into the drill chuck. |

| Body | The main part of the bit, which includes the cutting edges and flutes. |

| Tip | The pointed end of the bit that starts the hole. |

| Flutes | The grooves that remove chips from the hole. |

Applications

Forstner bits are widely used in various applications, including:

- Woodworking: Creating round holes for dowels, screws, and other fasteners.

- Plastic and Composite Materials: Drilling holes in materials like plastic, plywood, and MDF.

- Leather and Fabric: Drilling holes for stitching and other decorative purposes.

- Model Making: Drilling precise holes in small-scale models and prototypes.

Choosing the Right Forstner Bit

Selecting the appropriate Forstner bit for your project is crucial for achieving the best results. Here are some factors to consider:

- Material: Choose a bit made of HSS or carbide, depending on the material you’re working with.

- Size: Select a bit with the appropriate diameter for your project.

- Flute Design: Some bits have more flutes than others, which can affect the speed and chip removal.

- Tip Shape: The tip shape can impact the ease of starting the hole and the overall quality of the cut.

Maintenance and Care

Proper maintenance and care are essential for extending the life of your Forstner bit. Here are some tips:

- Store the bit in a dry, cool place to prevent rust and corrosion.

- Use cutting fluid or oil to lubricate the bit during use, which can help reduce heat and extend the bit’s life.

- Regularly inspect the bit for signs of wear and replace it when necessary.

Conclusion

The Forstner bit is a valuable tool for anyone involved in precision machining. With its versatile design and efficient performance, it has become a staple in many workshops. By understanding its history, design, applications, and maintenance, you can make the most of this versatile tool and achieve professional results in your projects.