Drill Bits for Stone Work: A Comprehensive Guide

When embarking on a stone work project, the choice of drill bits is crucial. Whether you’re a DIY enthusiast or a professional, understanding the different types of drill bits available for stone work can make a significant difference in the quality and efficiency of your work. In this article, we will delve into the various aspects of drill bits for stone work, including their materials, types, and usage.

Materials Used in Drill Bits for Stone Work

Drill bits for stone work are typically made from high-quality materials that can withstand the hardness and abrasive nature of stone. The most common materials used are:

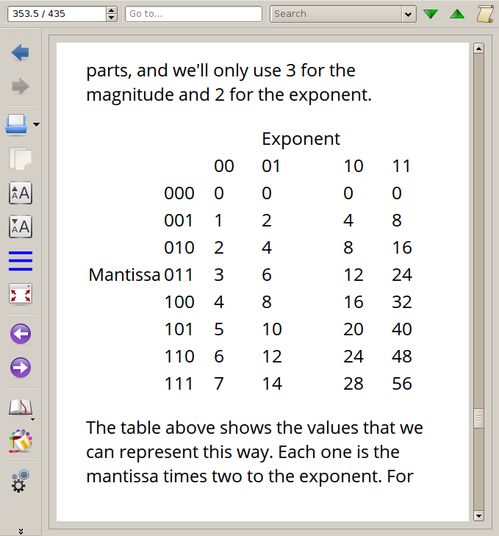

| Material | Description |

|---|---|

| High-Speed Steel (HSS) | High-speed steel is a versatile material that offers good durability and heat resistance. It is suitable for drilling into softer stones like marble and limestone. |

| Carbide | Carbide bits are made from tungsten carbide, a material known for its extreme hardness and durability. They are ideal for drilling into harder stones like granite and quartzite. |

| Ceramic | Ceramic drill bits are designed for drilling into extremely hard stones, such as sapphires and diamonds. They offer excellent heat resistance and durability. |

Each material has its own advantages and limitations, and the choice of material depends on the type of stone you are working with and the desired outcome.

Types of Drill Bits for Stone Work

There are several types of drill bits available for stone work, each designed to cater to specific requirements. Here are some of the most common types:

- Core Bits: These bits are used for drilling holes with a diameter larger than the bit itself. They are ideal for creating sockets for anchor bolts or for extracting cores from stones.

- Spade Bits: Spade bits are designed for drilling straight holes in stone. They have a wide, flat blade that allows for smooth and efficient drilling.

- Hole Saws: Hole saws are used for creating large, circular holes in stone. They come in various sizes and are suitable for projects like window and door installations.

- Core Drills: Core drills are similar to core bits but are designed for drilling holes with a diameter smaller than the bit itself. They are often used for electrical installations and plumbing work.

The choice of drill bit type depends on the specific requirements of your project and the type of stone you are working with.

Usage and Maintenance of Drill Bits for Stone Work

Proper usage and maintenance of drill bits for stone work are essential for ensuring their longevity and optimal performance. Here are some tips:

- Choose the Right Drill Bit: Select a drill bit that is suitable for the type of stone you are working with and the desired outcome. Using the wrong bit can damage the stone and the bit itself.

- Use the Correct Speed: The speed at which you drill can affect the quality of the hole and the life of the bit. Consult the manufacturer’s recommendations for the appropriate speed for your drill bit and stone type.

- Apply Proper Pressure: Applying too much pressure can damage the stone and the bit. Use a steady, controlled pressure while drilling.

- Keep the Bit Clean: After each use, clean the bit to remove any debris or stone chips. This will help maintain its sharpness and extend its lifespan.

- : Store your drill bits in a dry, cool place to prevent rust and corrosion.

By following these tips, you can ensure that your drill bits for stone work remain in good condition and provide reliable performance for years to come.

Conclusion

Drill bits for stone work are essential tools for any stone work project. By understanding the different materials, types, and usage of these bits, you can make informed decisions and achieve the best results. Remember to choose the right bit for your project, use the correct speed and pressure, and maintain your bits properly to ensure their longevity and optimal performance