Wood Hole Boring Bit: A Comprehensive Guide

When it comes to woodworking, the right tools can make all the difference. One such tool is the wood hole boring bit. This versatile accessory is designed to create precise holes in wood, allowing for a wide range of applications. In this article, we will delve into the details of wood hole boring bits, exploring their features, benefits, and how to choose the right one for your needs.

Understanding the Basics

A wood hole boring bit is a cutting tool that is used to create holes in wood. It is typically made of high-quality steel or carbide and features a sharp cutting edge. The bit is mounted on a drill or a router, and it rotates at high speeds to cut through the wood material.

Wood hole boring bits come in various sizes, ranging from small bits suitable for delicate work to larger bits for more substantial projects. The diameter of the bit determines the size of the hole it can create, so it’s important to choose the right size for your specific application.

Types of Wood Hole Boring Bits

There are several types of wood hole boring bits available, each with its own unique features and benefits. Here are some of the most common types:

- Spade Bits: These bits are designed to create large, straight holes. They are ideal for making pilot holes for screws or for creating large openings in wood.

- Forstner Bits: Forstner bits are similar to spade bits but have a flat bottom, which allows them to create clean, flat-bottomed holes. They are often used for making holes for hinges or for creating recesses for wooden plates.

- Brad Point Bits: Brad point bits have a small, pointed tip that helps to prevent the bit from wandering as it cuts. They are suitable for making precise holes in wood and are often used in conjunction with a router.

- Counterbore Bits: Counterbore bits are designed to create a larger diameter hole at the top of the hole, which allows for the insertion of a screw or bolt. They are commonly used in woodworking projects that require countersinking.

Features to Consider

When selecting a wood hole boring bit, there are several features to consider to ensure that you choose the right tool for your project:

- Material: High-quality steel or carbide bits are more durable and can withstand higher temperatures, making them ideal for heavy-duty applications.

- Coating: Some bits are coated with materials like titanium or Teflon, which reduce friction and heat, resulting in smoother cuts and longer bit life.

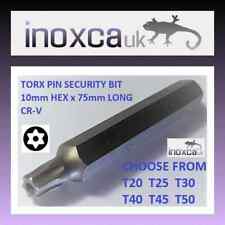

- Shank Type: The shank of the bit is the part that fits into the drill or router. Common shank types include straight shanks, hex shanks, and wood boring shanks. Choose a shank type that is compatible with your drill or router.

- Flute Design: The flute design of the bit affects chip ejection and cooling. A well-designed flute can improve cutting performance and extend bit life.

How to Choose the Right Size

Selecting the correct size of wood hole boring bit is crucial for achieving the desired results. Here are some tips for choosing the right size:

- Consider the Purpose: If you are making pilot holes for screws, choose a bit that is slightly smaller than the screw diameter. For larger holes, select a bit that is the desired diameter.

- Check the Material: Hardwoods may require a larger bit than softwoods to achieve the same hole size, as hardwoods are denser and more difficult to cut.

- Consider the Depth: Make sure the bit is long enough to reach the desired depth without binding or breaking.

Using a Wood Hole Boring Bit

Using a wood hole boring bit is a straightforward process. Here are the basic steps:

- Secure the Bit: Attach the wood hole boring bit to your drill or router using the appropriate shank type.

- Mark the Hole Location: Use a pencil or a marking gauge to mark the location of the hole on the wood surface.

- Start Drilling: Begin drilling at a low speed to prevent the bit from overheating