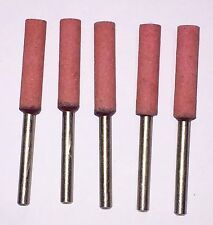

Grinding Bit: A Comprehensive Guide

Grinding bits are essential tools in various industries, from metalworking to woodworking. They are designed to remove material from a workpiece, creating smooth and precise finishes. In this article, we will delve into the different types, features, and applications of grinding bits, helping you make an informed decision for your next project.

Types of Grinding Bits

Grinding bits come in various shapes and sizes, each designed for specific tasks. Here are some of the most common types:

| Type | Description |

|---|---|

| Conical | Used for grinding internal and external surfaces, such as holes and grooves. |

| Fluted | Fluted grinding bits are ideal for removing material quickly and efficiently. |

| Segmented | Segmented grinding bits are used for grinding hard materials, such as cast iron and steel. |

| Ball-nose | Ball-nose grinding bits are used for creating rounded contours and fillets. |

Features to Consider

When selecting a grinding bit, it’s essential to consider several features to ensure optimal performance:

- Material: Grinding bits are made from various materials, such as high-speed steel (HSS), carbide, and ceramic. Each material has its advantages and is suitable for different applications.

- Coating: Some grinding bits have coatings, such as TiN (titanium nitride) or TiCN (titanium carbonitride), which improve wear resistance and reduce friction.

- Shank Type: Grinding bits come with different shank types, such as straight shanks, Morse tapers, and collets. Choose a shank type that is compatible with your machine.

- Length: The length of the grinding bit should be sufficient to reach the workpiece without causing excessive vibration.

Applications

Grinding bits are used in various industries and applications, including:

- Manufacturing: Grinding bits are used in manufacturing processes to create precise shapes and finishes on metal and plastic parts.

- Automotive: Automotive technicians use grinding bits to repair and maintain engine components, such as cylinder heads and camshafts.

- Woodworking: Woodworkers use grinding bits to shape and smooth wood surfaces, creating intricate designs and contours.

- Construction: Grinding bits are used in construction to cut and shape materials, such as concrete and stone.

Choosing the Right Grinding Bit

Choosing the right grinding bit for your project involves considering the following factors:

- Workpiece Material: Select a grinding bit made from a material that is suitable for the workpiece material. For example, use a carbide grinding bit for hard materials like cast iron and steel.

- Application: Consider the specific task you need to perform. For instance, a fluted grinding bit is ideal for removing material quickly, while a ball-nose bit is suitable for creating rounded contours.

- Machine Compatibility: Ensure that the grinding bit’s shank type is compatible with your machine’s spindle.

Maintenance and Safety

Proper maintenance and safety practices are crucial when using grinding bits:

- Maintenance: Regularly inspect your grinding bits for signs of wear and damage. Replace them when necessary to ensure optimal performance and safety.

- Safety: Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and ear protection, when operating a grinding machine.

By understanding the different types, features, and applications of grinding bits, you can make an informed decision for your next project. Remember to consider the workpiece material, application, and machine compatibility when selecting a grinding bit. Additionally, maintain your grinding bits and follow safety practices to ensure a successful and safe experience