Dremel Bits for Metal: A Comprehensive Guide

When it comes to metalworking, having the right tools is crucial. One of the most versatile tools in your arsenal is the Dremel bit. These bits are designed to cut, grind, sand, and polish metal with precision and ease. In this article, we will delve into the various types of Dremel bits for metal, their uses, and how to choose the right one for your project.

Types of Dremel Bits for Metal

Dremel offers a wide range of bits designed specifically for metalworking. Here are some of the most popular types:

| Bit Type | Description |

|---|---|

| Carbide Burrs | Used for cutting, grinding, and shaping metal. They come in various shapes and sizes, making them versatile for a wide range of applications. |

| Grinding Wheels | These bits are designed for grinding and smoothing metal surfaces. They come in different grit levels, with finer grits providing a smoother finish. |

| Carbide Tipped Cut-Off Wheels | Perfect for cutting through metal quickly and cleanly. They are ideal for making precise cuts in metal rods, tubes, and bars. |

| Carbide Bur Cutting Wheels | These bits are used for cutting and shaping metal, similar to carbide burrs. They are available in various shapes and sizes to accommodate different cutting needs. |

| Carbide Tipped End Mills | Used for drilling and cutting slots in metal. They are available in various sizes and shapes to fit different drilling requirements. |

Choosing the Right Dremel Bit for Metal

Selecting the appropriate Dremel bit for your metalworking project is essential for achieving the desired results. Here are some factors to consider when choosing a bit:

- Material: Different bits are designed for different types of metal. For example, carbide burrs are suitable for cutting and shaping metals like steel, aluminum, and brass, while grinding wheels are ideal for smoothing metal surfaces.

- Application: Consider the specific task you need to perform. For cutting, you’ll need a cutting wheel or a carbide tipped cut-off wheel. For grinding and smoothing, a grinding wheel or a carbide burr would be more appropriate.

- Size: The size of the bit should match the size of the workpiece. A bit that is too small may not cut effectively, while a bit that is too large may damage the workpiece.

- Shape: The shape of the bit should be suitable for the task. For example, a ball-end bit is ideal for cutting curves, while a straight bit is better for cutting straight lines.

Using Dremel Bits for Metal

Using Dremel bits for metal requires proper technique and safety precautions. Here are some tips to help you get the most out of your Dremel bit:

- Secure the Workpiece: Make sure the workpiece is securely clamped or held in place to prevent it from moving during the cutting process.

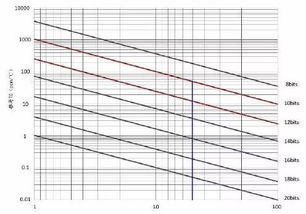

- Choose the Right Speed: Dremel bits operate at different speeds, so choose the appropriate speed for the material and task. Generally, slower speeds are better for cutting and grinding, while higher speeds are suitable for sanding and polishing.

- Apply Light Pressure: Applying too much pressure can damage the bit or the workpiece. Use light pressure and let the bit do the work.

- Keep the Bit Clean: Regularly clean the bit to remove metal shavings and debris. This will help maintain the bit’s performance and extend its lifespan.

Conclusion

Dremel bits for metal are an invaluable tool for any metalworker. With the right bit, you can achieve precise cuts, smooth finishes, and intricate designs. By considering the type of material, application, size, and shape of the bit, you can choose the perfect tool for your project.