Dremel Carbide Bit: A Comprehensive Guide

Are you looking to enhance your precision and efficiency in crafting intricate projects? Look no further than the Dremel Carbide Bit. This versatile tool is a must-have for anyone who values quality and durability. In this detailed guide, we will delve into the various aspects of the Dremel Carbide Bit, including its features, benefits, and applications. So, let’s get started!

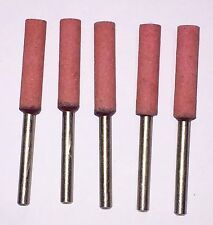

Understanding the Dremel Carbide Bit

The Dremel Carbide Bit is a high-quality cutting tool designed for use with Dremel rotary tools. It is made from carbide, a hard and durable material that provides excellent cutting performance. The bit features a shank that fits securely into the chuck of a Dremel tool, allowing for precise and controlled cuts.

Carbide bits are available in various shapes and sizes, each designed for specific applications. Whether you need to cut, grind, or sand, there is a carbide bit that can help you achieve your desired results.

Features of the Dremel Carbide Bit

Here are some of the key features that make the Dremel Carbide Bit stand out from other cutting tools:

- High Durability: Carbide is a hard material that can withstand high temperatures and abrasive materials, making it an excellent choice for tough cutting tasks.

- Sharp Edges: The carbide tips on the bit are extremely sharp, allowing for clean and precise cuts.

- Wide Range of Applications: Dremel carbide bits are suitable for various materials, including wood, metal, plastic, and ceramic.

- Easy to Use: The bits are designed to fit securely into the chuck of a Dremel tool, ensuring a stable and safe cutting experience.

Benefits of Using the Dremel Carbide Bit

Using a Dremel Carbide Bit offers several advantages, including:

- Increased Efficiency: The sharp edges and durable construction of the bit allow for faster and more efficient cutting.

- Improved Precision: The carbide tips provide clean and precise cuts, reducing the need for additional sanding or finishing work.

- Cost-Effective: The long-lasting nature of carbide bits means you won’t need to replace them as often as other cutting tools.

Applications of the Dremel Carbide Bit

The Dremel Carbide Bit is a versatile tool that can be used for a wide range of applications, including:

- Woodworking: Cutting, sanding, and shaping wood for furniture, cabinets, and other woodworking projects.

- Metals: Cutting, grinding, and shaping metal for metalworking projects, such as jewelry making, metal sculptures, and metal fabrication.

- Plastics: Cutting, sanding, and shaping plastic for model making, hobby projects, and other plastic crafting tasks.

- Ceramics: Cutting and shaping ceramics for pottery, tile work, and other ceramic projects.

Choosing the Right Dremel Carbide Bit

With so many different types of Dremel carbide bits available, it can be challenging to choose the right one for your project. Here are some tips to help you make the best choice:

- Material: Consider the material you will be working with. Different bits are designed for specific materials, such as wood, metal, or plastic.

- Application: Think about the specific task you need to perform. For example, a cutting bit is ideal for making straight cuts, while a sanding bit is better for smoothing surfaces.

- Size: Choose a bit that fits your Dremel tool and the size of the project you are working on.

How to Use the Dremel Carbide Bit

Using a Dremel Carbide Bit is straightforward. Here’s a step-by-step guide to help you get started:

- Attach the Bit: Insert the carbide bit into the chuck of your Dremel tool and secure it tightly.

- Choose the Speed: Adjust the