Understanding Industrial Drill Bits: A Comprehensive Guide

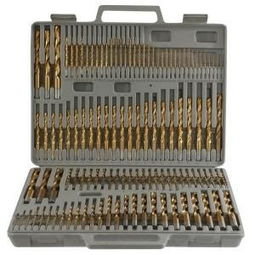

Industrial drill bits are essential tools for various applications, from construction to manufacturing. Whether you are a professional tradesperson or a DIY enthusiast, understanding the different types and uses of industrial drill bits can greatly enhance your productivity and efficiency. In this article, we will delve into the world of industrial drill bits, exploring their features, benefits, and applications.

Types of Industrial Drill Bits

There are several types of industrial drill bits, each designed for specific materials and tasks. Here are some of the most common types:

| Type | Description |

|---|---|

| High-Speed Steel (HSS) | Used for drilling metal, wood, and plastic. It is versatile and suitable for general-purpose drilling. |

| Carbide-Tipped | Excellent for drilling through hard materials like cast iron, stainless steel, and non-ferrous metals. They are more durable than HSS bits. |

| Titanium Coated | Provides better heat resistance and longer life than HSS bits. Ideal for drilling through high-temperature materials. |

| Wood Drill Bits | Specifically designed for drilling wood, these bits have a sharp point and a wide flute to remove wood chips efficiently. |

| Concrete Drill Bits | Used for drilling through concrete, brick, and masonry. They are made of high-quality materials to withstand the hardness of these materials. |

Features to Consider When Choosing Industrial Drill Bits

When selecting industrial drill bits, there are several features to consider to ensure you get the right tool for the job:

- Material Compatibility: Choose a bit that is suitable for the material you will be drilling. For example, carbide-tipped bits are ideal for drilling through hard materials, while HSS bits are versatile for general-purpose drilling.

- Bit Size: The size of the bit should match the size of the hole you need to create. Using the wrong size can lead to poor performance or damage to the bit.

- Flute Design: The flute design affects the bit’s ability to remove chips from the hole. A wide flute is better for drilling wood, while a narrow flute is suitable for drilling metal.

- Shank Type: The shank is the part of the bit that fits into the drill chuck. Common shank types include straight shank, hex shank, and SDS-plus.

Benefits of Using Industrial Drill Bits

Using industrial drill bits offers several benefits, including:

- Increased Productivity: The right drill bit can significantly reduce the time it takes to complete a task.

- Improved Accuracy: High-quality drill bits ensure precise holes, which is crucial for many applications.

- Reduced Tool Wear: Using the appropriate bit for the job can extend the life of your tools.

- Enhanced Safety: Properly sized and designed drill bits reduce the risk of accidents and damage to the workpiece.

Applications of Industrial Drill Bits

Industrial drill bits are used in a wide range of applications, including:

- Construction: Drilling holes for electrical wiring, plumbing, and other installations.

- Manufacturing: Creating holes for assembly, fastening, and other production processes.

- Automotive: Drilling holes for bolts, screws, and other components.

- Woodworking: Drilling holes for screws, dowels, and other joinery techniques.

- Home Improvement: Drilling holes for mounting shelves, pictures, and other fixtures.

Conclusion

Industrial drill bits are essential tools for a wide range of applications. By understanding the different types, features, and benefits of these bits, you can make informed decisions and improve